RAM Inc. Engineering

RAM’s Engineering Department is staffed to meet the exacting standards of today’s component design requirements. Our six degreed engineers bring over 100 years of experience in product design and development. Our engineers have been trained in GD&T and have received training in the programming of our CMM which verifies conformance of customer drawing and contractual requirements to our Quality Assurance department. Our engineering and quality teams have also been trained to use and program our Digital Vision Inspection System. Our personnel have access and understanding of all current ASTM, MIL, ASE, DOD, and DFAR specifications to meet our customer’s requirements.

*RAM’s customers maintain design control of all product built and delivered

Our engineering team has also been trained in PPAP (Production Part Approval Process) and is well versed in both Process and Design FMEA’s. This, along with A3-8D problem solving tools, enables us to develop and implement strong manufacturing processes while maintaining a program of continuous improvement.

In order to achieve our goal of total customer satisfaction, we utilize all engineering and design tools available to us. Our systems ensure that efficiency, courtesy and professionalism are maintained in a manner that complies with product integrity and program schedule requirements. We often work closely with our customers during the product design phase which results in the production of quality components on time and at optimal cost.

RAM provides the Following Engineering services

- LASER Scanning

- ASTM Testing

- Material Testing

- Reverse Engineering

- X-Ray Testing

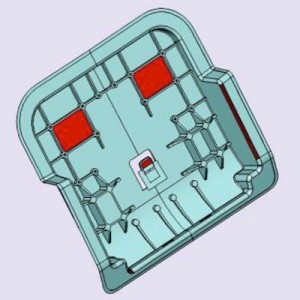

- Mold Flow Analysis

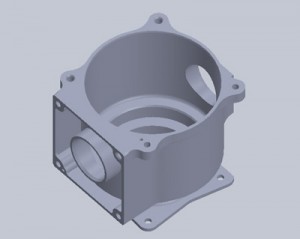

- Tool Design

- Component Design Consultation

- Metal-to-Plastic Design coordination

RAM Utilize the Following Engineering tools:

RAM Utilize the Following Engineering tools:

- Solidworks

- Solidworks Plastics Module

- PC-DMIS

- CAMWorks

- Digital Vision Inspection System

Mold Analysis Slideshow

Our Mission:

- Producing Quality Molded/Machined Components

- Conforming Parts On Time

- Direct and Transparent Communication with Our Customers

- Compliance with all customer specifications

- Complying with RAM’s internal AS9100 Guidelines

You may click on the hyperlinks below to learn more about some of our suppliers:

|

|

|

|