Engineered to Meet Demanding Aerospace Specifications

Choose RAM, Inc.’s engineered plastics and turn the tables on traditional aerospace and defense materials. Achieve the ideal balance between durability and lightness.

Built to Withstand the Demands of Aerospace and Defense

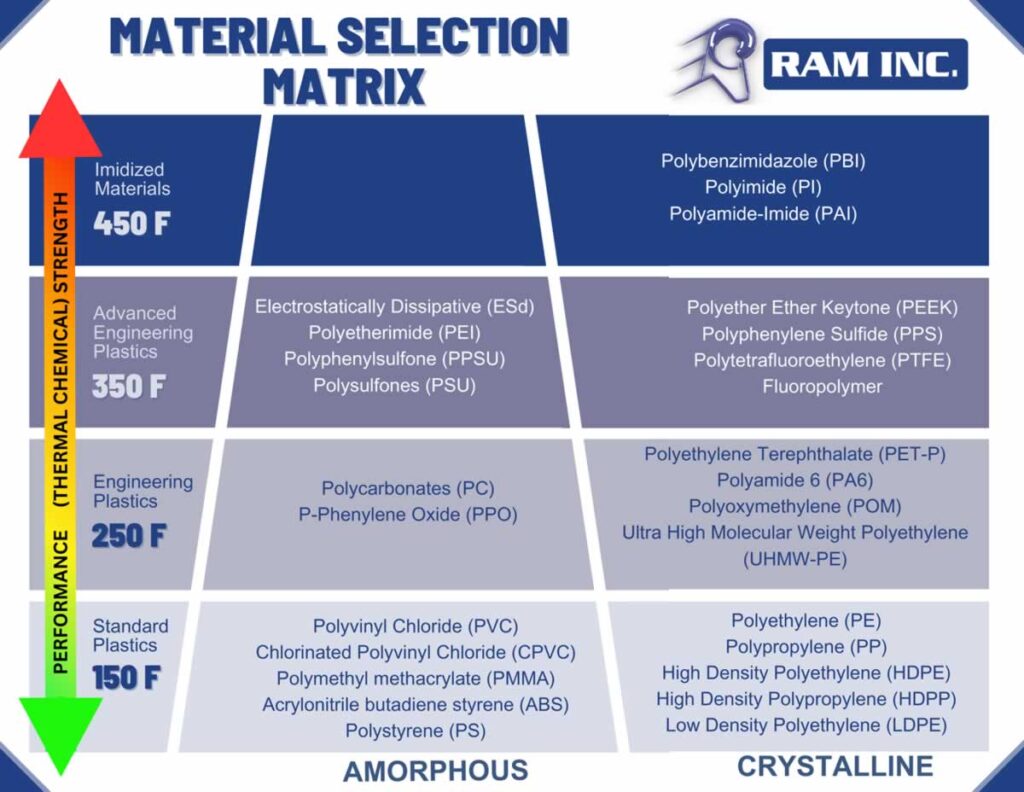

We use a variety of engineered plastics to produce high-quality components for the aerospace and defense industries.

Engineered plastics are materials that have been designed to meet specific performance requirements, such as high strength, impact resistance, and temperature stability.

These materials are ideal for use in applications where traditional plastics are not strong enough or where metal components are too heavy.

Engineered Plastics

At RAM, we use a variety of engineered plastics on a daily basis – these are just a few examples. We work closely with our customers to ensure conformance to required specifications.

PEEK (Polyether ether ketone)

PEEK is a high-performance thermoplastic that is known for its excellent mechanical properties, high temperature resistance, and chemical resistance. It is often used in aerospace and defense applications where high strength and stability are required.

Ultem (Polyetherimide)

Ultem is a high-strength thermoplastic that is used in a variety of aerospace and defense applications. It is known for its excellent dimensional stability, high temperature resistance, and chemical resistance.

Polycarbonate (PC)

Polycarbonate is a transparent thermoplastic that is known for its excellent impact resistance, high temperature resistance, and dimensional stability. It is often used in aerospace applications where visibility and durability are important.

Nylon (Polyamide)

Nylon is a tough and flexible thermoplastic that is used in a variety of aerospace and defense applications. It is known for its high strength, impact resistance, and chemical resistance.

Acetal (Polyoxymethylene)

Acetal is a high-strength thermoplastic that is known for its excellent dimensional stability and resistance to chemicals and abrasion. It is often used in aerospace and defense applications where precise components are required.

Liquid Crystal Polymer (LCP)

Liquid Crystal Polymer (LCP) resins facilitate processing in injection molding equipment. They provide fast cycle times and high flow into thin sections. They provide exceptional dimensional stability with very low shrinkage and warpage and high temperature resistance.